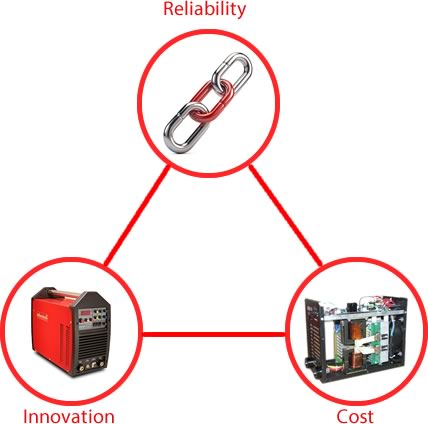

I got to thinking this morning about how digital inverter welders have impacted the product range and pricing of inverter welding machines available in Australia today. The evolution of welding machines is driven by three influencing factors.

1. The manufacturer must offer relevant and technologically advanced welding machines in order to attract customers.

2. The manufacturer must keep production costs low in order to offer competitively priced welding machines.

3. The manufacturer must consider building reliable welding machines in order for their brand to be trusted and flourish.

The diagram above shows a simplified explanation of this relationship. Enter the digital inverter welder.

Digital Inverter Welders

Digital inverter welders use microprocessors to process a program and then send signals to relevant parts of the welding power source to switch components in order to obtain the desired result. A change in the program can produce a different result without any requirement to modify the actual hardware. This is different to analogue inverter welders which contain electronic circuits made up mostly of discrete components that are hard wired to do a job and cannot be changed easily after manufacture.

The advantages offered by digital inverter welding power sources is that one control board can be used in many different welding machines be it TIG or MIG or MMA and simply changing the program can change the operational mode of the welding machine. Within the Metalmaster range of welding machines one control board and one front interface control panel is used to drive the Metalmaster Alupulse 210 Pro, Metalmaster Alupulse 320 Pro, Metalmaster 215 Elite, Metalmaster 256 Elite welding machines. Apart from the welding power source output components that control the electrical load, only the digital program and front plastic membrane differs in each of the models, the electronics behind the front panel and the main control boards are identical. This is an example of how one digital design can have multiple applications and reduce manufacturing costs.

digital inverter welder control panel

Digital Inverter Welder Reliability

Tokentools welding machines have established a reputation in Australia of reliability and longevity. Our industry standard 5 year warranty is founded in the components used for the power train of our inverter welders. We were the first to use Infineon IGBT transistors in our welding machines whilst other manufacturers were running MOSFET output stages. Our control circuits implement Motorolla, Siemens, Fairchild, NEC components and although this drives manufacturing costs up, the reliability is increased which brings costs down overall as future cost allowance for warranty work is reduced.

The next time you are looking to buy a new welder it will be easier to decide which model and brands to pick by applying the 3 criteria outlined above. Look for the machine with the most features, best price and longest warranty. If you would like more information, please give our staff a call on 1300 991 881 or any of our state based direct in-dial numbers.