Psst, you need weld cleaning machines, they are used by the pros!

Welding of stainless steels affects the chromium density of the surface which leads to poor appearance and subsequent corrosion when left untreated. There are a few way to clean up post weld and if you do a lot of stainless welding you want to avoid that nasty pickling paste process and invest in an electropolishing machine.

Why the machine, well, the best way to post-weld finish stainless steel is by electropolishing, which for those not in the know is an electrochemical process that rebuilds chromium throughout the weld surface by increasing it’s density and as a result restores the chromium’s ability to create an oxide film.

stainless steel weld with heat affected zone that is lacking chromium oxide

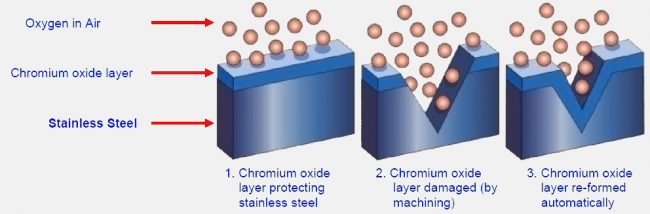

Stainless steel is corrosion resistance due to the formation of a chromium oxide film that forms the protective layer naturally on the surface of the stainless steel. This chromium oxide film is strongly adherent despite it being quite thin but most importantly it is chemically stable which is commonly referred to as ‘passive’. The chromium oxide film is created when chromium reacts with oxygen. Interestingly you may have seen some stainless steel rusting with a surface effect called tea staining. This is caused when dirt on the surface of the stainless prevents the oxygen molecules from bonding with the chromium and rust appears. By keeping the stainless clean the chromium oxide layer is kept intact and the passive property of rust prevention remains active.

So why does welding have an effect on stainless steel joints? The welding process adds extreme heat and this causes severe chromium depletion not only at the weld surface but through out the weld affected area, that is the portion that was heat affected. By only using a mechanical process and limiting the removal of surface material such as oxide scale only half the job is done as the weld area remains chromium depleted with regards to the original components of parent stainless steel.

It is critically important that stainless steel does not lose chromium from the surface, when the weld heat affected zone becomes is depleted of chromium, the surface corrosive resistance level is severely reduced and the weld along with it’s boundary that is heat affected is therefore vulnerable to corrosion and other effects such as loss of reflectance and poor cosmetic appeal. Would you buy a spit roast from stiffy if he had dodgy looking welds, no way. Below is a graphic showing the molecular structure of the chromium oxide layer.

Introducing the modern labour saver, the electropolishing machine. Electropolishing selectively dissolves the microscopic high points of the stainless and selectively removes iron so increases the chromium density and creates a microscopically smother surface on which bacterial contamination cannot bind or hide.

Many years ago, back in the transistor radio dark ages, electropolishing of stainless steel could only be performed by the immersion of the work piece in an electrolyte solution. As you can imagine, due to the varied sizes and shapes of weld sections this wasn’t always possible, practical or cost effective.

Australian ingenuity coupled with dogged determination has produced several stainless weld cleaning machines. With the Metalscience mepBLITz and TIG CHAMP BRUSH DC PLUS it is now possible to weld and then immediately after cooling finish the same weld with a mirror like finish that is chromium dense. It doesn’t matter if you weld on-site or in the workshop, each and every weld can be processed easily as the electropolishing rig is portable and runs on 240V single phase supply.

The Metalscience stainless cleaning machines require minimal labor to be invested in producing great results so in effect yield faster production than other cleaning processes and put savings into your pocket. The mepBLITz uses a food grade acid that combines a phosphoric acid with several sequestering agents to deliver a dramatic improvement in operator safety.

The mepBLITz and TIG CHAMP BRUSH DC Plus range of electropolishing products will return the characteristic properties of stainless steel to it’s maximum effect of being chromium rich, metallically clean and free from stress, a smoother surface with reduced microscopic cracks, minimum absolute surface area and chemically passive.

Contact the sales team at Tokentools on 1300 881 991 if you would like to seek more information or you can follow the link to our electropolishing equipment here to buy online within Australia